THE HISTORY OF MARBLE

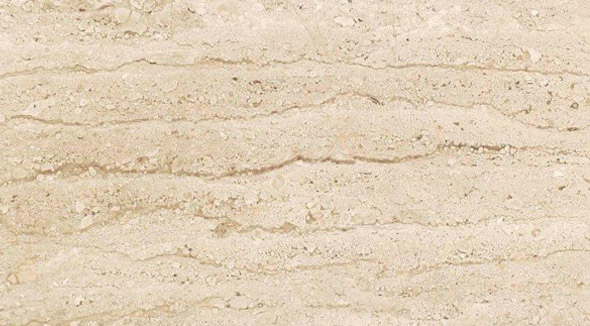

From its origins, to extraction and processing, the Sardinian marble obtains an extraordinary feature that distinguishes each single product. The marble comes from a carbon formation with origins dating back to the Jurassic and Cretaceous period. From a geological point of view, the rock belongs to the family of sedimentary rocks classified by shells, seashells, minerals and algae crystallized in the stone, giving live to countless shades and types of marble.

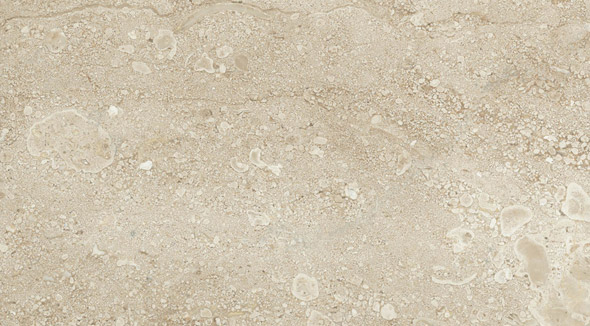

DAINO IMPERIALE

VENETIAN MARBLE

The veined marble is a medium-grained white marble with large gray veins, more or less regular, which often form textures. It can also have large spots.

NUVOLATO MARBLE

Nuvolato marble takes its name from its appearance reminiscent of the shape of clouds. Its light beige color interspersed with white patches of pure calcite gives it that refined appearance and makes it suitable for the most elegant contexts.

PERLATO MARBLE

The name Perlato derives from the splendid appearance of this marble which makes it one of a kind. It is a marble with unique characteristics that make it suitable for outdoor and largescale works.

Fiocco di Neve

The name Fiocco di Neve derives from the characteristic aspect of this marble. It is a marble mostly suitable for the realization of works for interiors, objects, etc. The main feature is the light color with snow effect.

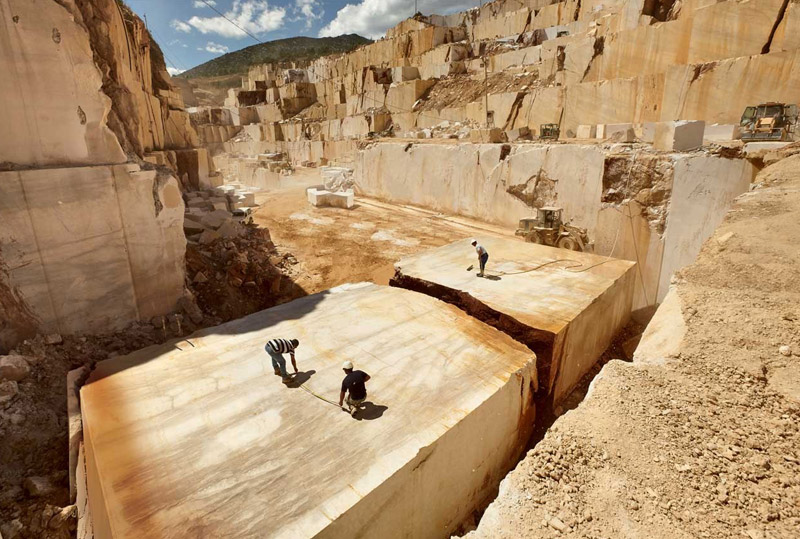

EXTRACTION

MARBLE EXTRACTION

The extraction of marble dates back to the mid-1950s. The quarries of Orosei in particular could supply marble for at least another two or three centuries.

All products are entirely handmade by experts in cutting and artists who passionately create exclusive and personalized works.

PRODUCTION

PRODUCTS PRODUCTION

C.N.C. MACHINE

The processing of the products takes place with the aid of numerical control machines (C.N.C.) for the roughing of the piece.

REFINING

It must then be refined by hand with diamond wheels and pneumatic cutters, chisels and inks, then finish with abrasive discs of different grain.

LATHE AND GRINDER

For pots and planters, the void is made on the lathe with a diamond wheel and then finished off, per requests, smoothened, bush-hammered or strip-chiseled by hand.